I. Why Heat Transfer Technology is the Ultimate Solution for Phone Case DIY?

Low Cost, High Returns.A basic setup costs only a few hundred yuan, with per-unit production costs as low as ¥3. Customized finished products can sell for tens or even hundreds of yuan, offering huge profit margins.

Explosion in Personalized Demand.Custom phone cases represent a billion-yuan market, with 90% of users willing to pay a premium for unique designs. DIY equipment efficiently handles small-batch orders (e.g., event gifts, influencer collaborations).

Natural Content Marketing Material.Process videos (e.g., “Printing a celebrity-style case in 3 minutes” on TikTok or Youtube) easily go viral, driving traffic to online stores.

Stunning Results.Heat transfer permanently bonds high-definition patterns (photos, illustrations, gradients) onto phone cases without fading, peeling, or texture changes. The finish remains smooth as factory-original.

Operational Flexibility.Whether for small-scale customization or mass production, heat transfer adapts seamlessly. One machine = unlimited business opportunities.

II. Core of Heat Transfer DIY: Equipment & Parameters Decoded

Professional Vacuum Heat Transfer Machine (Recommended for Commercial Use)

- Structure (Simplified patented design):

- Lid + Base: Hinged for easy access; base embeds heating elements (tubes/plates).

- Vacuum System: Base includes vacuum ports (connected to a pump) ensuring transfer film adheres tightly to curved surfaces.

- Sealing Mechanism: Silicone gaskets clamp the film, preventing air leaks and misalignment.

- Workflow:

- Cover case with printed heat transfer film, secure using high-temperature tape.

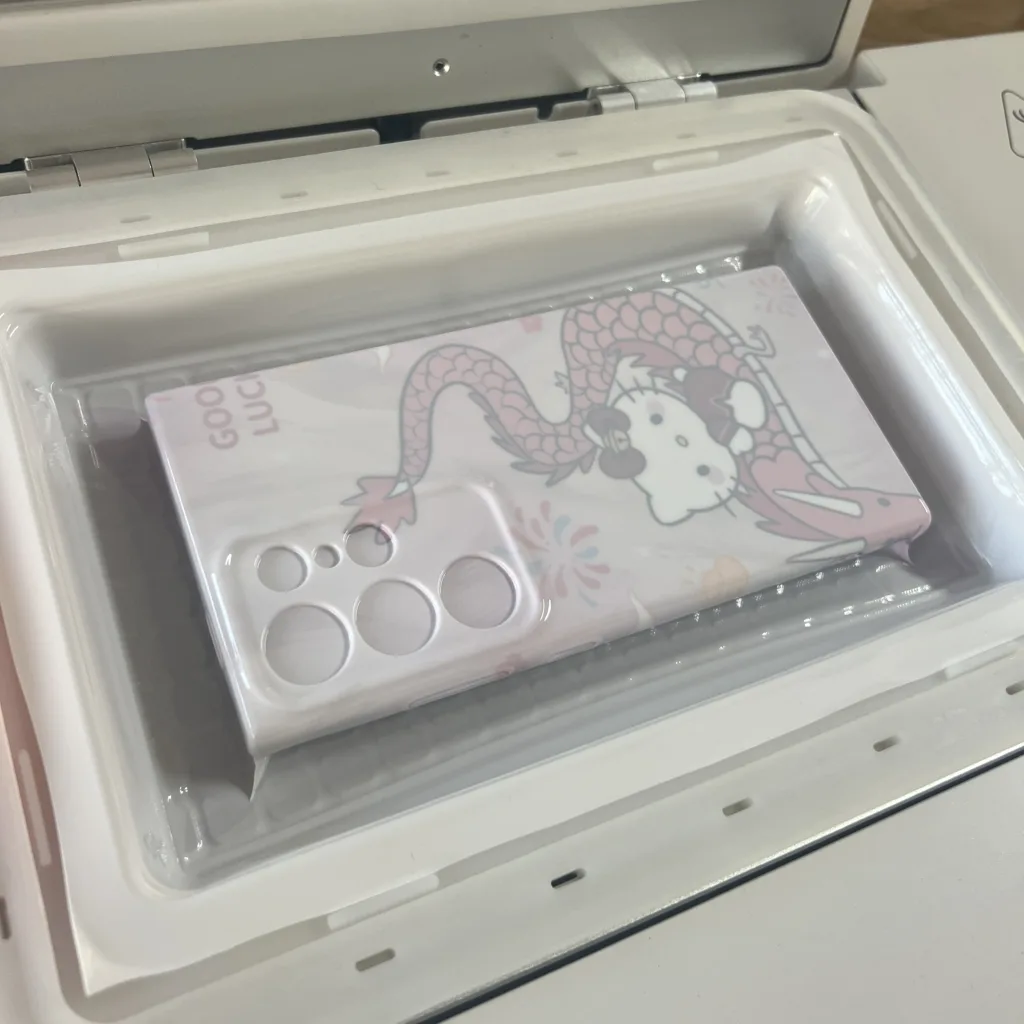

- Close lid → Activate vacuum → Heat (230°C, 180 seconds) → Cool and demold.

- Outcome: Bubble-free edges, 300% improved scratch resistance.

III. Step-by-Step DIY Process

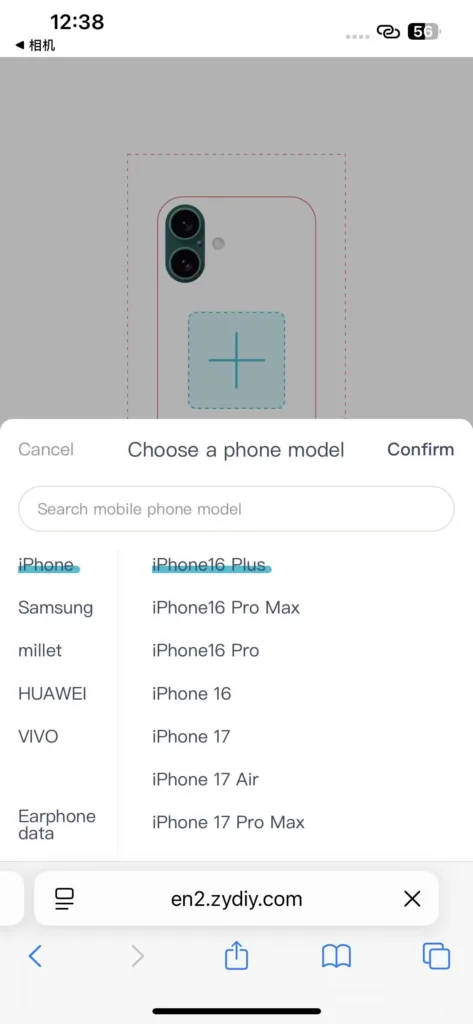

Step 1: Design Your Pattern

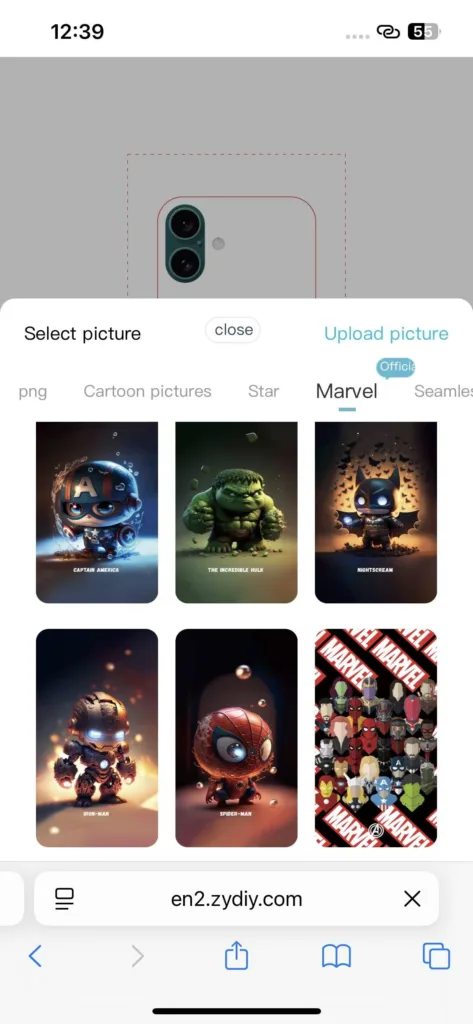

- Use PS or tools like Canva; upload to design platforms.

- Inspiration: Nostalgic pixels / Abstract gradients / Pet portraits.

Step 2: Print & Transfer

- Print: Use heat transfer ink on specialized paper.

- Positioning: Align pattern face-down on the case.

- Heat Press: Close lid to activate vacuum + heating.

Step 3: Final Reveal

- Peel & Cool: Remove film while warm; air-cool for 30 seconds → Glossy, durable finish.

IV. Pitfall Avoidance: Tips for Beginners!

- Case Material: PC or PET hard cases (withstand >180°C).

- Blurry Prints: Ensure resolution ≥300dpi; avoid touching film before ink dries.

- Edge Lifting: Insufficient vacuum → Check/replace silicone gaskets or add weights.

V. From DIY to Entrepreneurship

Top-Selling Design Directions:

- Memory Keepsakes: Couple photos + date engravings.

- IP Collaborations: Anime characters + embossed effects (adjust pressure for 3D textures).Low-Cost Startup Kit:Heat transfer machine (238$)+BlankPCcases(0.35$/unit) + Transfer paper (0.3$/sheet)= <0.7$/unit cost; sells for $9–19!

✅ Conclusion: Your Creativity Deserves the Spotlight!

Heat transfer DIY isn’t just a technique—it’s a magic that transforms ordinary objects into art. Whether you’re a hobbyist or an entrepreneur, this machine is your key to creative wealth.🔥 Take Action Now:

Contact me

- Download the [Heat Transfer Parameter Cheat Sheet] + [20 High-Traffic Design Templates].

- Explore our equipment guides, troubleshooting community, and design library—go from novice to pro instantly!

This guide covers technical fundamentals. Equipment operation must comply with safety standards. Data sourced from: China National Standard for Heat Transfer Technology (GB/T 23444-2009)